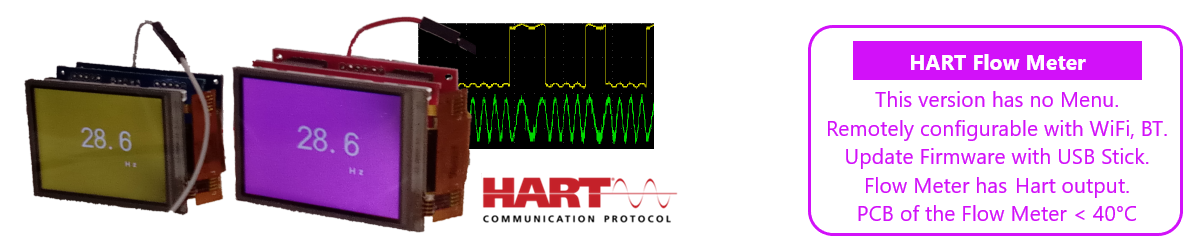

a Vision is that, further step is in the digitalization of the Flow Meter. Another dimension opens where we could gain in precision and simplicity compared to the classic Flow Meter. When we talk about interfacing with the instrument, one thinks first of his Mobile Phone and activates the app, then reads the value, then opens the menu and manipulates as if the Flow Meter is at the front of him, when the instrument can be mounted in Pipes 20 Meters above.

Imagine that you are at the front of a huge Petrochemistry factory, like a Petrol platform where many Flow Meters are mounted. A Tablet can interface to all these Flow Meters, displays their positions on a virtual Photo of the Petrol Platform as active shining points. Then one just clicks on a Flow Meter and a window prompts with all measured values and parameters, such as the flow in Liter/min, Medium in the Pipe (Benzin, Water, ..), Temperature, Pressure, Flow Meter label, SN, Software version.

Imagine that you are at the front of a huge Petrochemistry factory, like a Petrol platform where many Flow Meters are mounted. A Tablet can interface to all these Flow Meters, displays their positions on a virtual Photo of the Petrol Platform as active shining points. Then one just clicks on a Flow Meter and a window prompts with all measured values and parameters, such as the flow in Liter/min, Medium in the Pipe (Benzin, Water, ..), Temperature, Pressure, Flow Meter label, SN, Software version.

Then if one Flow Meter is broken, it must be replaced. Shell the whole Pipe be replaced too? and the cost and the work? We solved this, by clone and replace the broken board for just few Dollars cost all included, and no need for Valve or Pipe removal, because we have the serial Nr. and we know the calibration factors of that Flow Meter.

Then if the Pressure in the Pipe rises above the maximum allowed, an 80dB Alarm is integrated in the Flow Meter and alerts loudly.

Then if the Medium changed from Benzin to Diesel in the Pipe, shell we replace the Flow Meter against another calibrated for Diesel? We replace nothing, because many calibration Parameters of many Mediums are stored in the Flow Meter, just select the Medium from the Menu and the Flow Meter will initialize for the selected Medium. And if the Medium Profile must be adjusted because of the Stoichiometry, what to do? We do!

Our technology did not stop there, we can calibrate without Liquid, a technique called dry-calibration, and this is very needed when we operate with a flammable or toxic Medium.

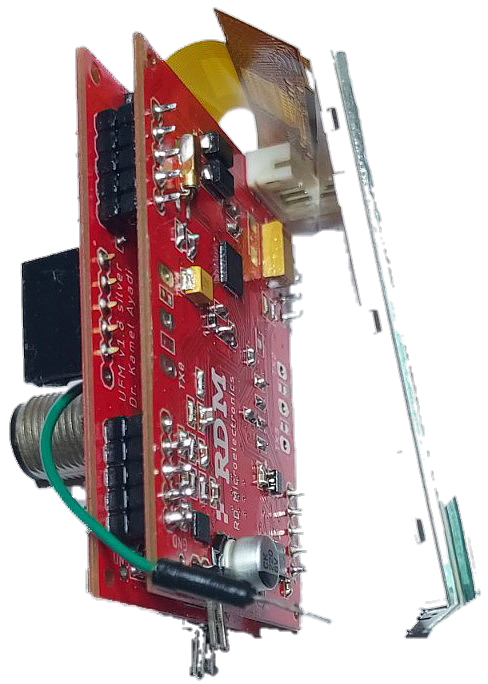

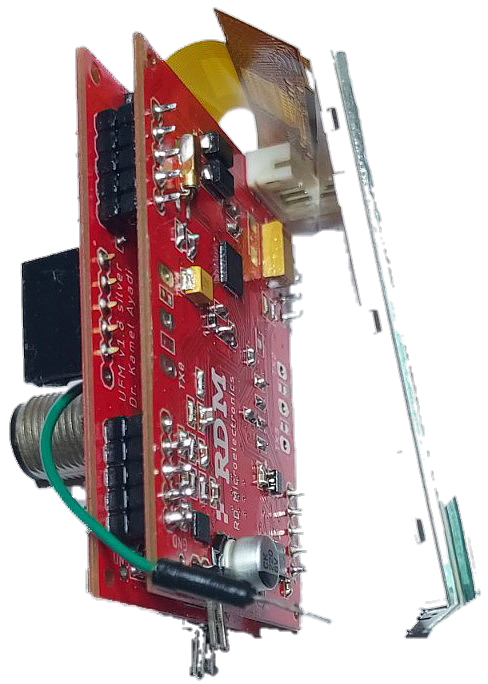

Thus, we develop Electronic and produce PCB, we program the firmware, and we calibrate the Flow Meter accordingly to meet the Vision.

Imagine that you are at the front of a huge Petrochemistry factory, like a Petrol platform where many Flow Meters are mounted. A Tablet can interface to all these Flow Meters, disp

Imagine that you are at the front of a huge Petrochemistry factory, like a Petrol platform where many Flow Meters are mounted. A Tablet can interface to all these Flow Meters, disp